Design and production for industrial moulds

Is your company searching for an efficient, reliable partner for all types of moulds?

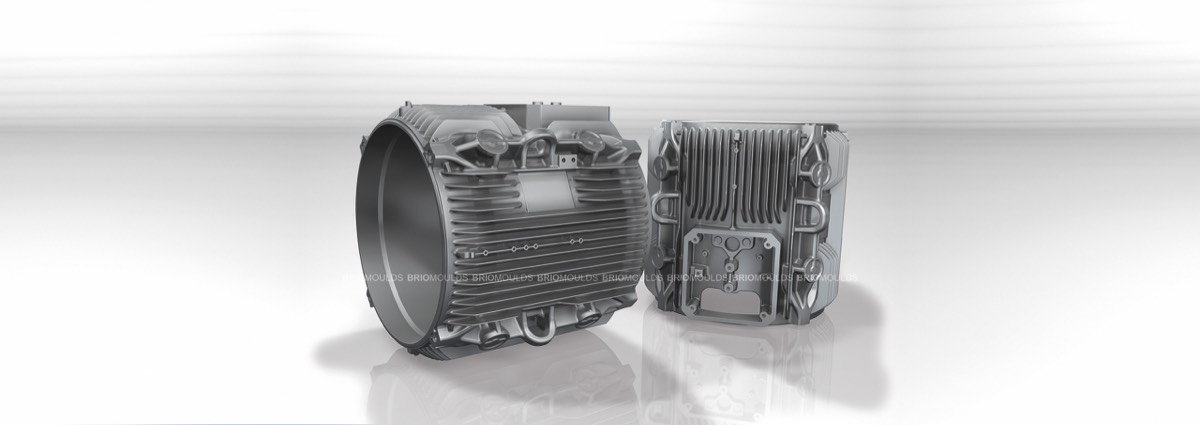

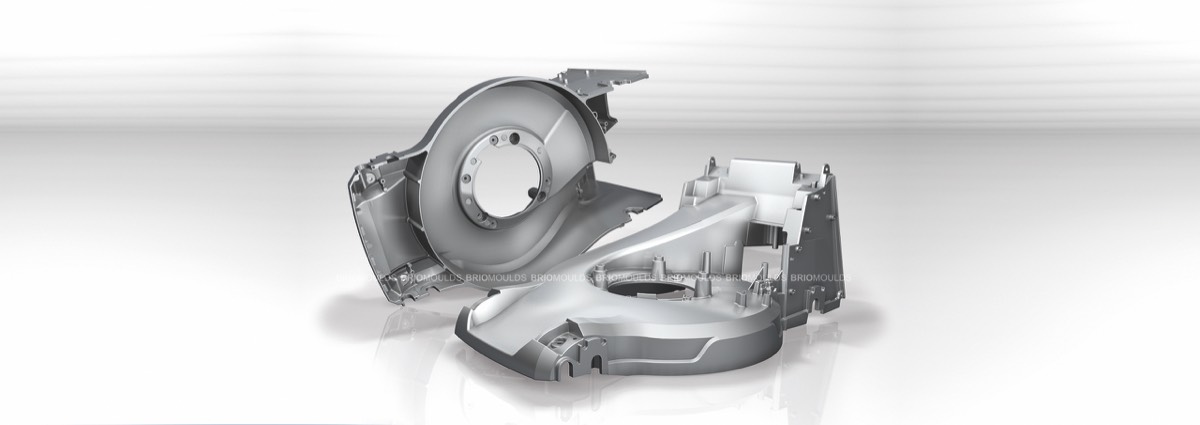

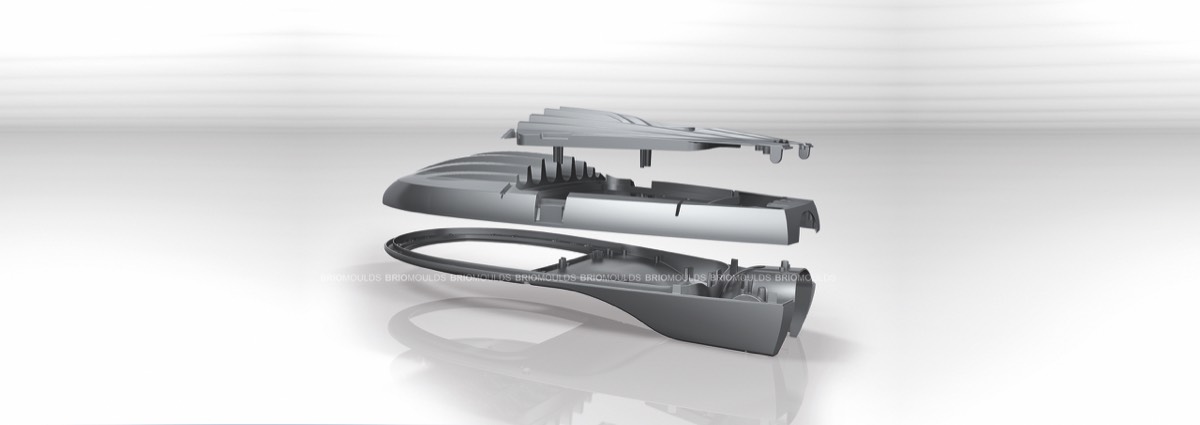

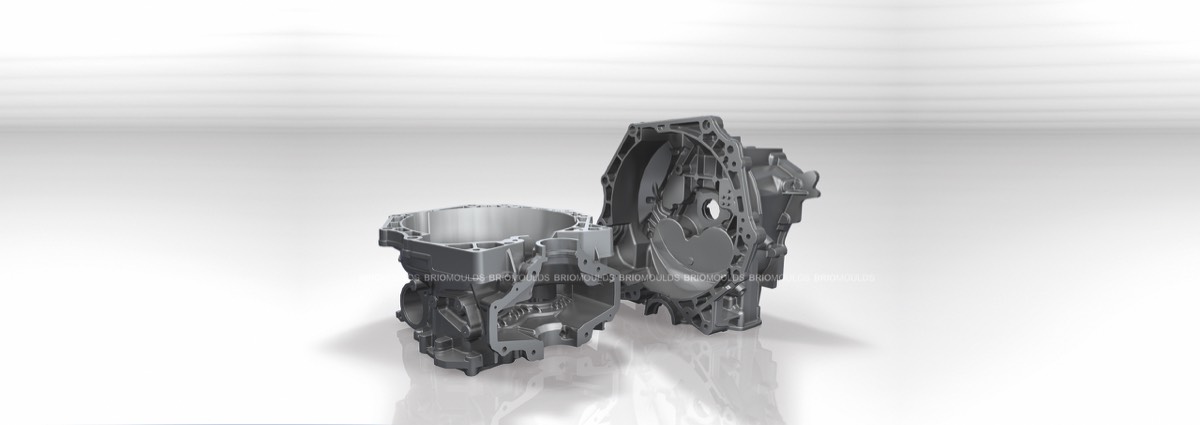

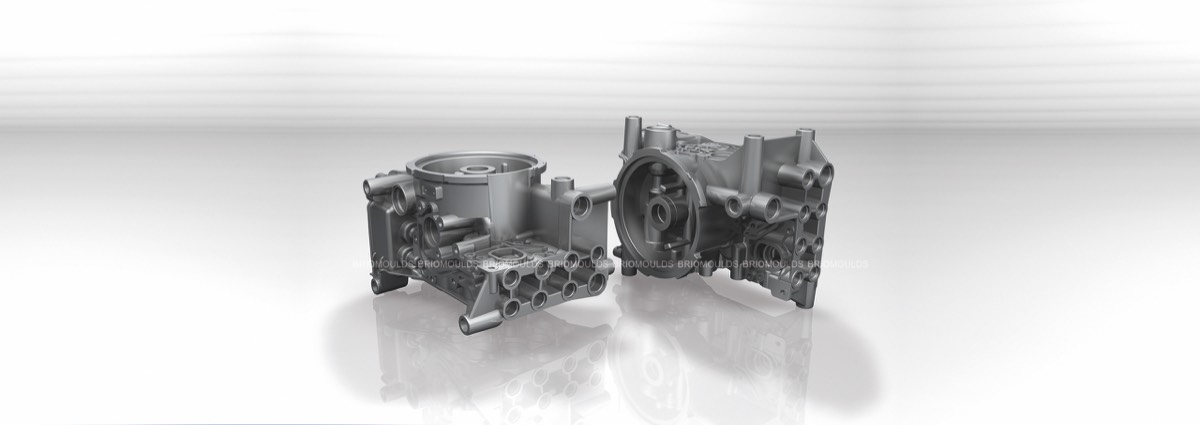

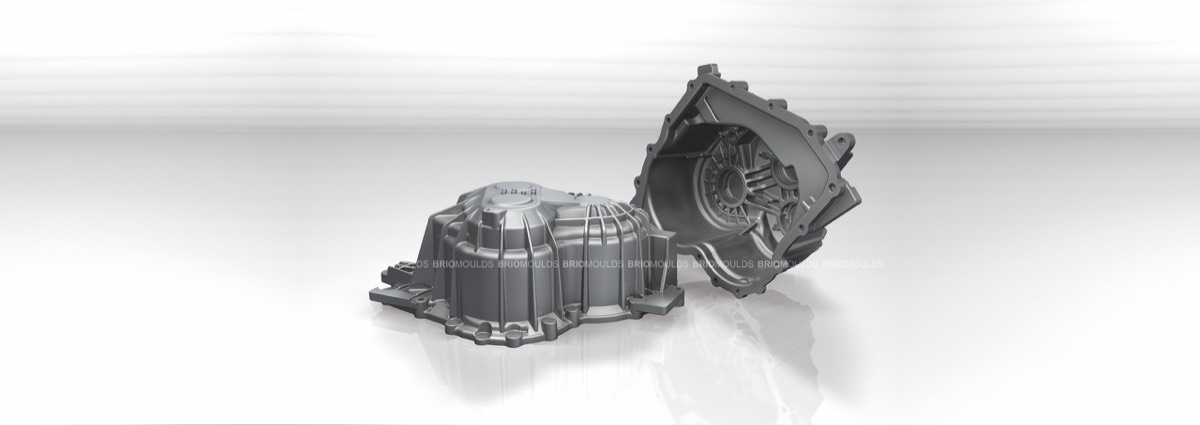

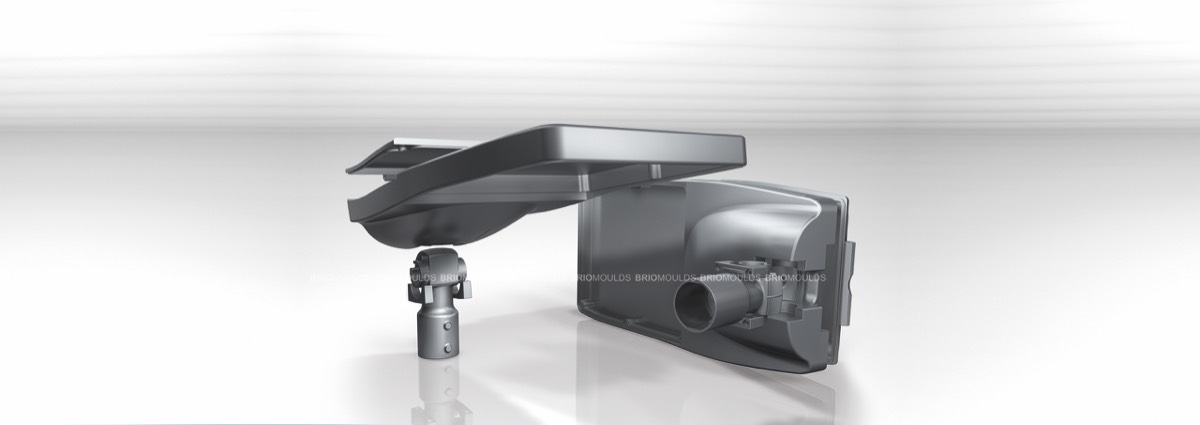

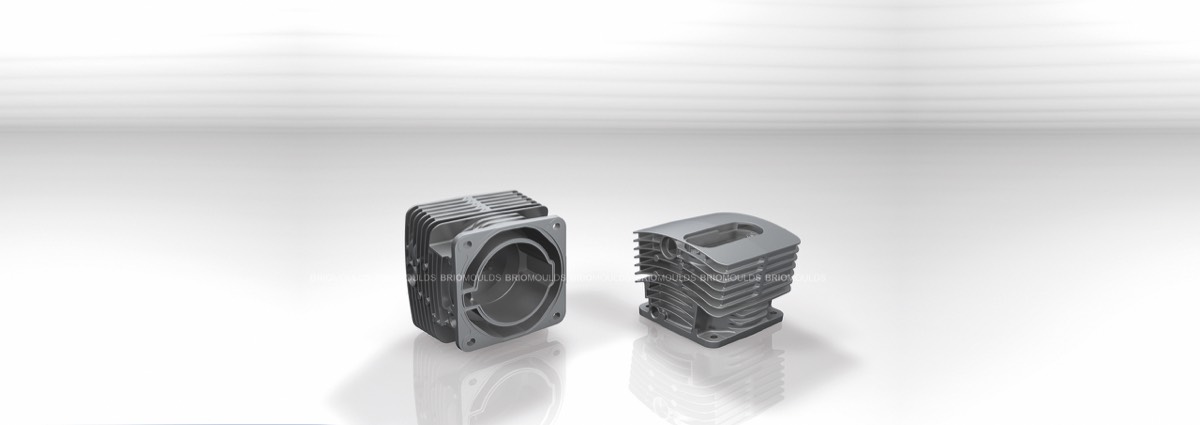

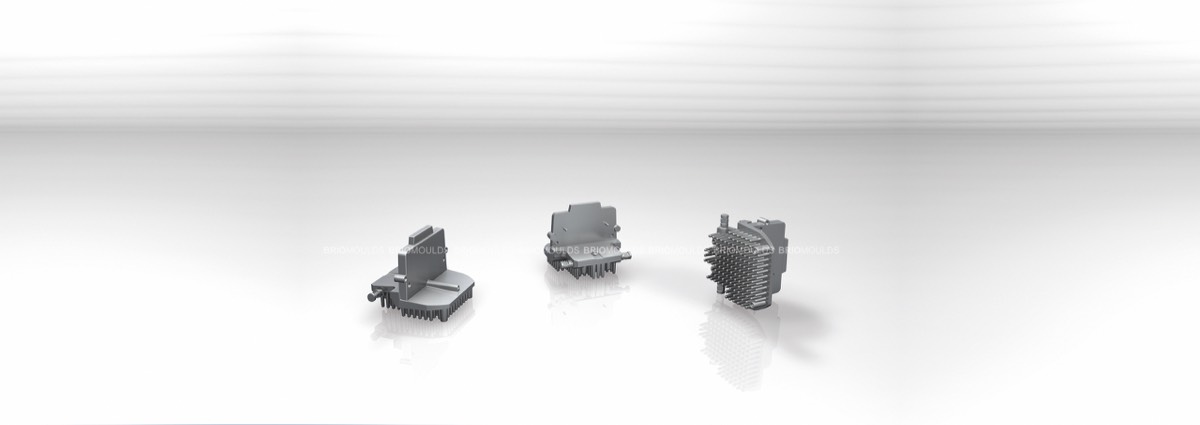

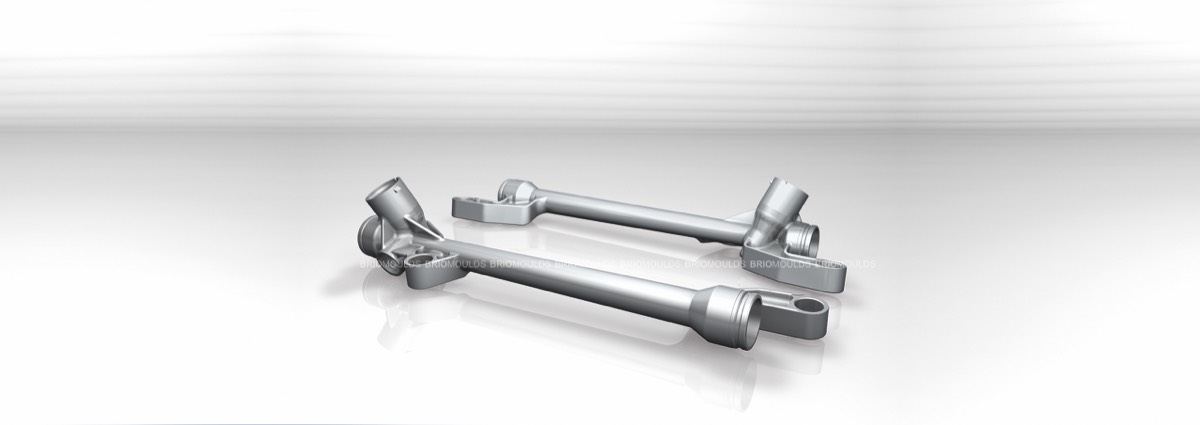

Brio Moulds designs and produces moulds for aluminium and magnesium die-casting and plastic injection. We put the care of craftsmen behind our products and deliver on-time to make your work easier, no matter the industrial sector.

Excellence in industrial mould production.

- Since 1997, Made in Italy and excellence in mould production for die-casting of aluminium, magnesium and plastic injection

- Two generations and total dedication to the perfection of each and every mould.

- 5000 sq m of floor space full of technology, flexibility and craftsmanship.

- Referenced experience in the production of moulds for all industrial environments.

- Technical consultation and precisely detailed quotes, delivered quickly.

- Partnerships and quality relationships for solutions which are in-line with your production objectives.

- Guaranteed delivery and production times which are monitored throughout the process.

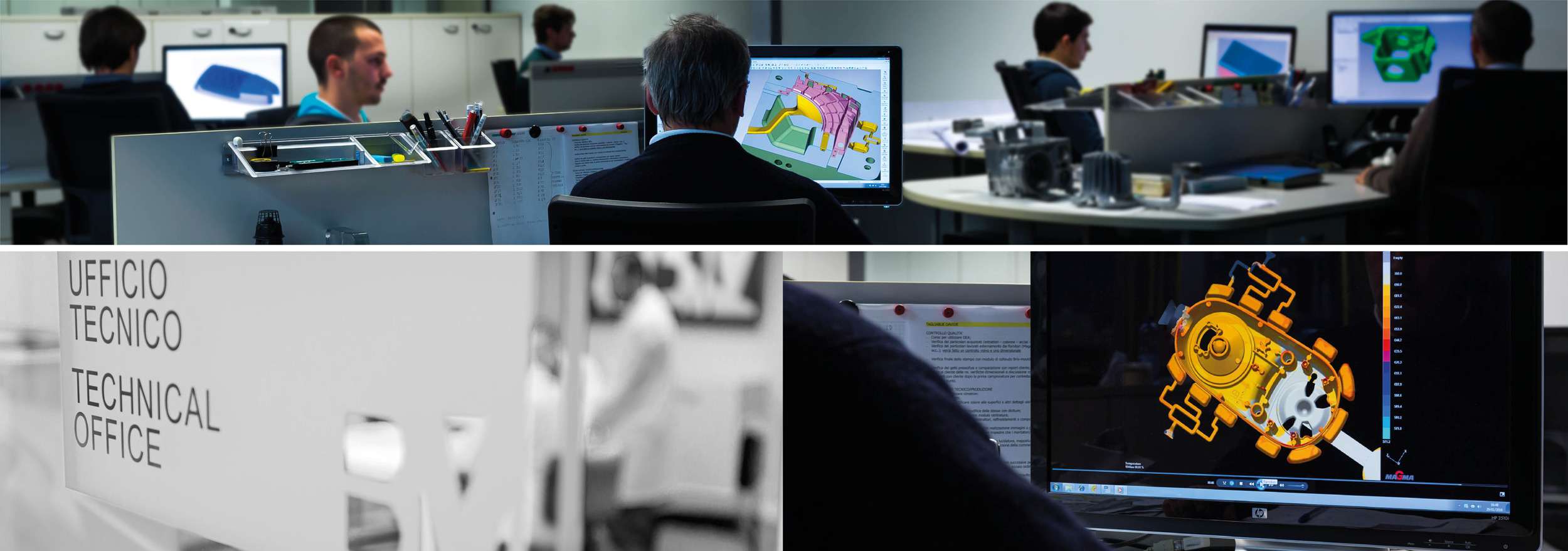

Quality planning from the initial idea to perfect casting.

- Consultation and verification of the feasibility of the mould’s design.

- Consultation services to improve the productivity of die-casting and injection moulds.

- Project analysis and industrial development of the client’s idea.

- Rapid prototyping with various materials.

- Simulation of mould filling and functionality.

- Constant technical updates and training.

- Design and production of die-cast and injection moulds, even with custom specifications created to suit the client’s needs.

Quality production for highly effective, durable moulds.

- Mould production for aluminium and magnesium die-casting and plastic injection machines from 50 to 3000 tonnes.

- Seven pick-up systems with double hoists for up to 48 tonnes.

- Samples and pre-series for die-casting production.

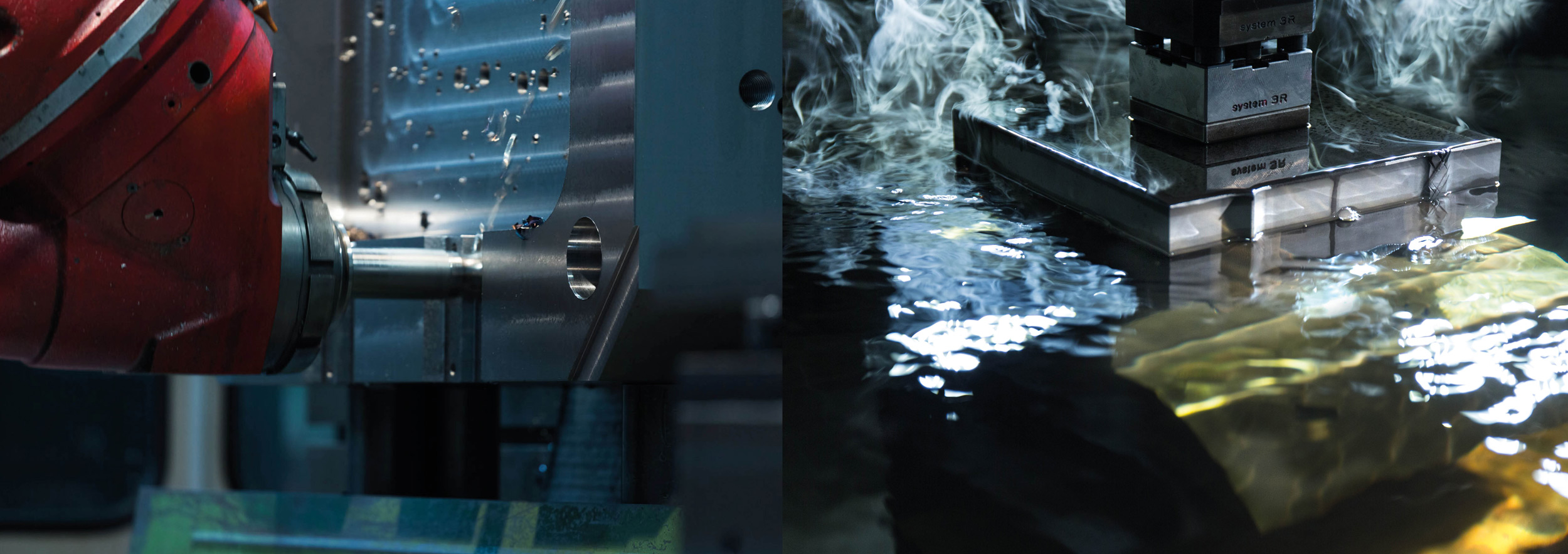

Quality in every working process for maximum precision moulds.

- High-precision automated production centres to manufacture moulds with machining range up to 5.5 m.

- High-speed machining centres with 3-4-5 axes with a machining range up to 1.5 m.

- Specialised professional abilities and complete technical competence.

- Constant investments to meet high production standards.

Die-casting and injection moulds of every size, up to 50 tonnes.

Download the brochure

Hand-crafted care for the finishings of each mould.

- Four assembly departments and die quality control.

- Completion, cleaning and reprocessing of the moulds with specialised safe liftings.

Certified quality with metrology: the company’s no-compromise philosophy.

- On-time delivery.

- Certification of raw materials and heat treatments.

- Metrology and certification services.

- Metrology centre with systems to check measurements for parts up to 2.2 m.

- 360° collaboration with companies in the industry.

- Certified and guaranteed quality for all die-casting and injection moulds.

- Compliance with minimum tolerances and standards established in the specifications.

6 great reasons to choose quality moulds for quality castings

1

Ability to listen to clients’ needs concerning moulds for aluminium, magnesium and plastic.

2

Quick turnaround on detailed, precise quotes for your moulds.

3

Analysis and industrial scaling of the project with mould filling simulation for die-casting and injection production.

4

Die-casting or injection mould production for machines from 50 to 3,000 tonnes with high-precision machining centres.

5

Pre-series die-casting for quality tests. Metrology services and mould certification..

6

On-time, scheduled delivery with production times that can be checked during the die productioncycle.